Manual flexible packing of fragile and sensitive parts, surfaces and material has been done almost in the same way for the past 20 years; technology has almost been standing still. During the same period of time the need of rational cost efficient and protective packing solutions has increased dramatically.

There are unstable, fragile and sensitive, parts, surfaces and products that need to be protected in most markets, segments and brands in automation-, telecom-, aircraft-, military-, electronics-, glass-, furniture-, medical industry etc. They all require perfect products!

Damages due to bad and unstable packing cost companies lots of money, time and reputation that could be saved if the goods where packed correctly the first time. Companies that are using “just in time” and lean production philosophy suffers from these problems extra much, since damaged goods often must be replaced in extremely short time (very expensive).

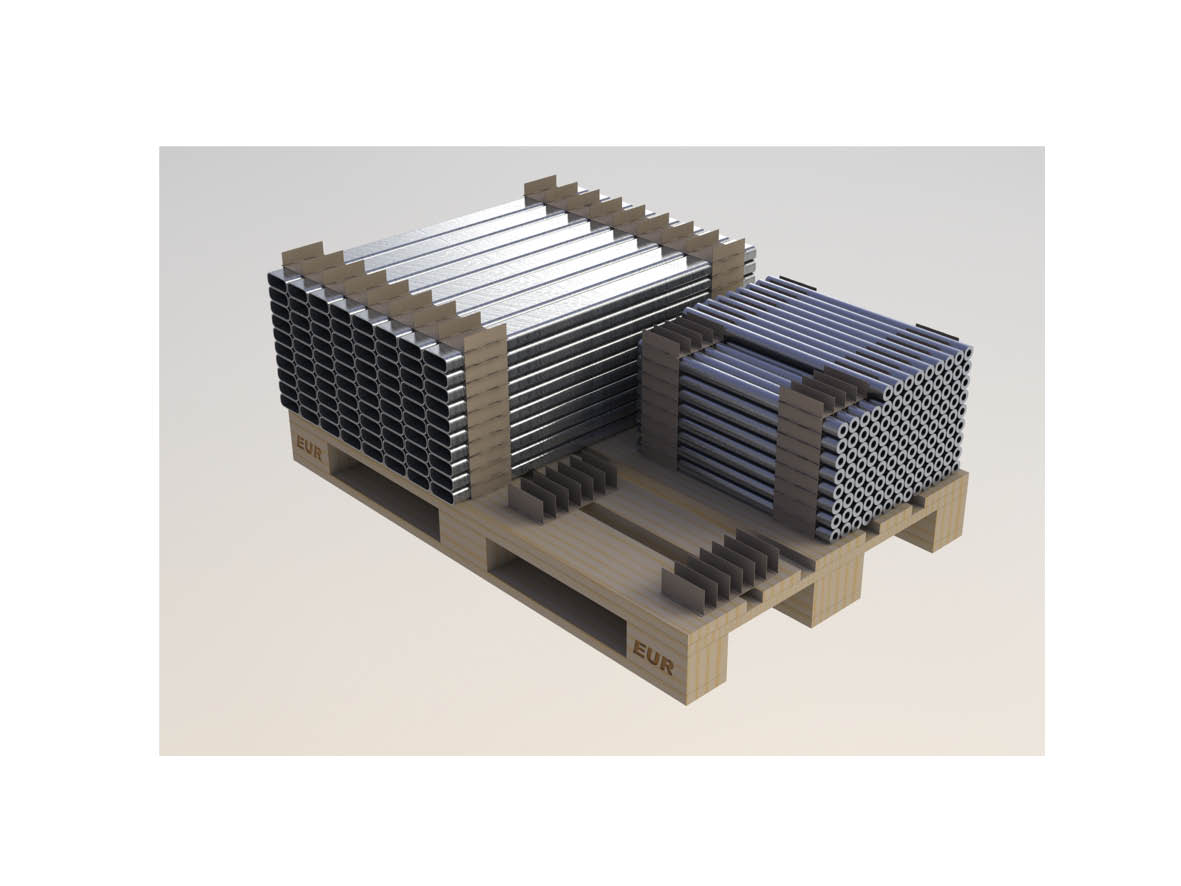

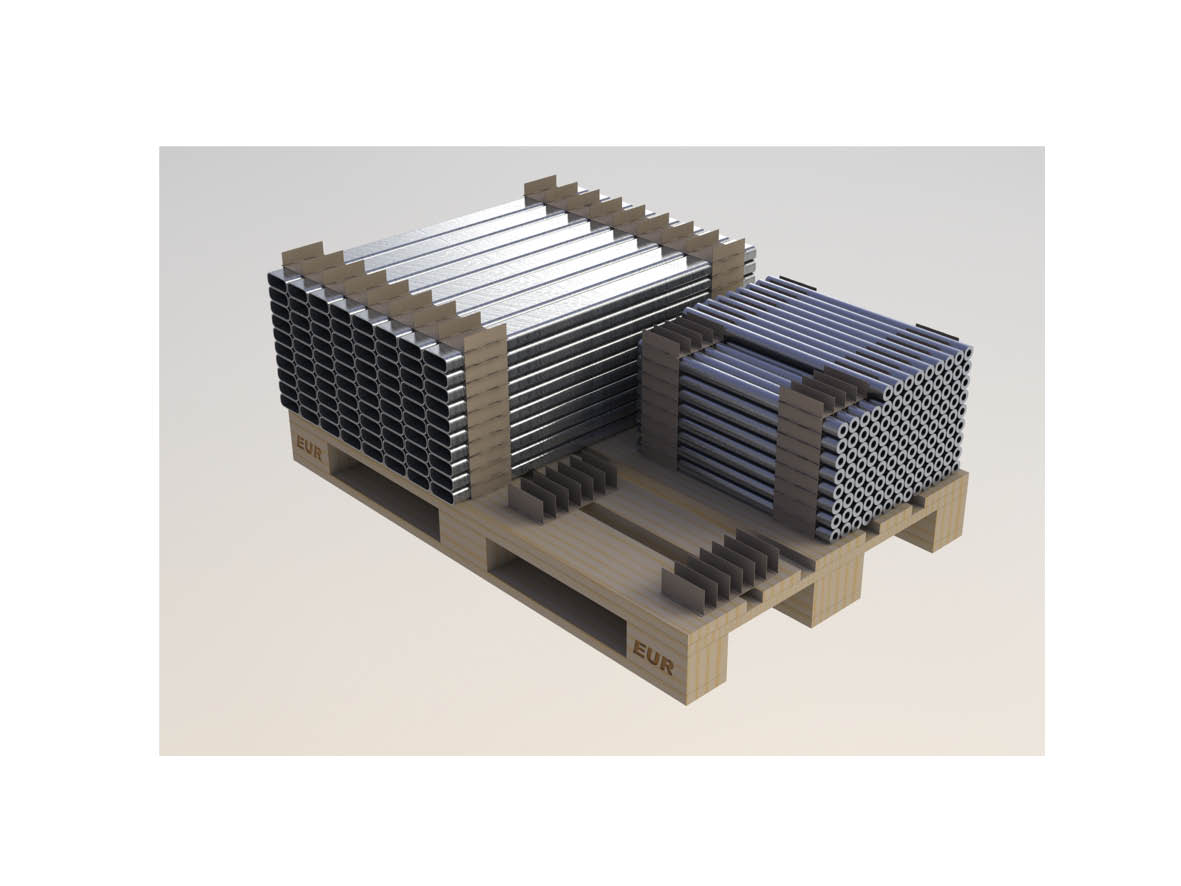

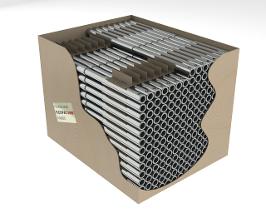

The FLEXICOMB has maximum flexibility since it could be tailor made produced in small quantities as well as for high volume production. There are no set-up times when changing between different configurations to be produced. All in the same machine and very cost efficient! Basic packing material to keep in stock is always the same; it is 99mm wide carton rolls and hot-melt glue. There is no need of keeping various and special types of packing material. It cannot be easier or more flexible!

The FLEXICOMB will minimize your costs for transportation damages; you will save time, money and environment as well as your reputation as a good and reliable supplier. You will also save a lot of time and money compared with ordering packing material or doing the packing material by yourself but in the old fashioned way!

© Copyright WALLTEC - WT-FLEXIPAC